As stated previously, liquid filling is vital to a business that requires liquid packaging to be rapid and efficient, for which the liquid filling machine manufacturer must be chosen well. No matter what you are bottling, be it beverages, pharmaceuticals or chemical products, you need a high-quality and highly capable Liquid filling machine to ensure the efficiency and quality of your operation. Generating In-Depth Insight On The Best Types Of Coffee Being Manufactured Introducing This Guide Here Are Detailed Tips That Can Help You To Choose The Most Appropriate Manufacturer As Well As Ensure You Acquire A Machine That Fits Your Needs

Analyze Technology Capabilities

In evaluating possible makers, look for those with some form of facility for cutting-edge equipment. The best liquid filling machine will have the most up to date technology including; servo driven automation, PLC control systems, and touch-screen interfaces. These capabilities increase precision in the filling process, with accuracy rates usually to ±0.5%, and also facilitate a fast set-up for various product viscosities and container sizes.

Production Speed Reqiurements

One important parameter is the speed of the liquid filling machine. Machine speeds depend on your production needs and can range from 20 containers a minute for a supsension to over 300 containers a minute for a water-like product. Make sure the manufacturer can supply a machine which may keep up with your current rate demands, but also has the capability to grow with your company.

Verify Your Product Compatibility

Now, each filling machine would not be perfect for every kind of liquid. Liquid Filling Machine by Product Type: Make sure the liquid filling machine manufacturer you choose to work with has prior experience working with your type of product. If you are using corrosive materials, for instance, the maker should be offering machines constructed with materials like stainless steel, or coated with layers that would resist corrosion.

Check the Robustness and the Maintenance of the Machine

Only consider manufacturers who have a reputation for creating sturdy, reliable machinery. Over time, that can translate to a reduction in downtime and maintenance costs for the life of the machine. Also, think about the maintenance services provided by the manufacturer. Widespread support, from spare part accessibility to regular maintenance, and 24/7 customer service, can go a long way towards extending the life of operation of your filling equipment.

Compliance and Certifications Audit

Make sure the manufacturer is compliant with the right industry standards and safety requirements-especially if you operate in a sector like food and beverages or pharmaceuticals. ISO, CE and FDA approval and other certifications are your best proof that the equipment operates as you expect and that your use case meets the context the product has been tested for such that it is safe and reliable.

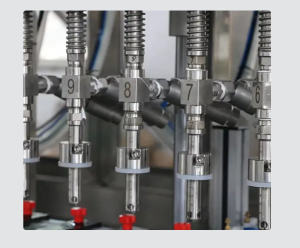

Find Customization Options

Last but certainly not least, a star of the machinery layout for rostering of your particular production line. Be it integration with existing conveyor systems, multi-filling nozzles or special sensors for fill-level detection, customization by the manufacturer to suit your plant requirements will provide a better and holistic solution.

Picking The Right Partner For Success

To sum up, in order to choose the suitable liquid filling machine manufacturer, is important to assess his technological know-how, his machine production speed, the compatibility or product, equipment sustainability, regulations compliance and customization options. By taking all of these factors into account, you can invest into a liquid filling solution that both improves your production efficiency, complies with industry norms, and is flexible to expand with your growing business.